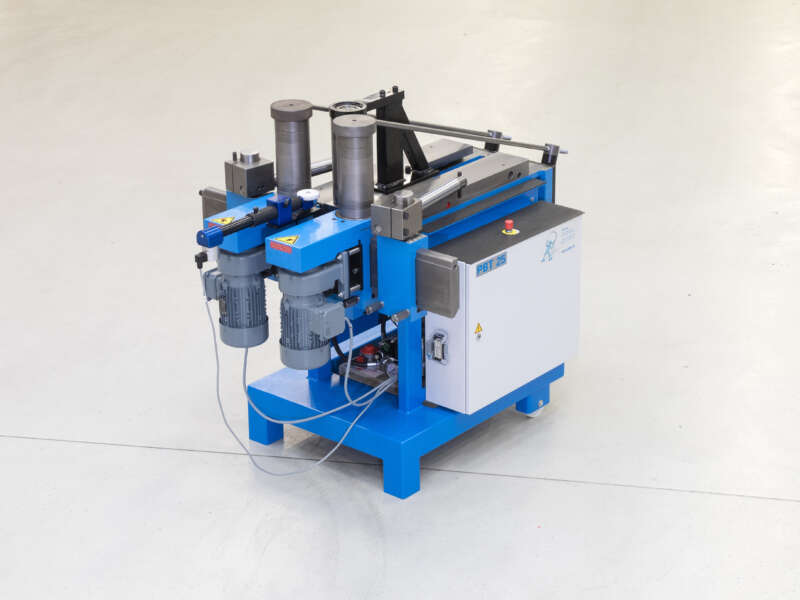

PBT profile bending machines overview

| ARKUS12 | PBT15 | PBT25 | PBT35 Servo Wide | HELIX Servo | |

|---|---|---|---|---|---|

| X-axis | |||||

| Force X-axis | 12 t | 15 t | 27 t | 35 t | 65 t |

| Positioning accuracy of the X-axis | 0,01 mm | 0,01 mm | 0,01 mm | 0,01 mm | 0,01 mm |

| Drive of X-axis | Valve controlled hydraulics | Valve controlled hydraulics | Valve controlled hydraulics | SERVOHydraulics clean - low noise - 70% energy savings |

SERVOHydraulics clean - low noise - 70% energy savings |

| Stroke of X-axis | 200 mm | 300 mm | 265 mm | 390 mm | 445 mm |

| Max. insertion width | 135 mm with roll ring D105 60 mm with bending device |

263 mm with roll ring D105 238 mm with roll ring D130 |

243 mm with roll ring D150 | 293 mm with roll ring D150 (optionally 350 mm with roll ring D150) |

415 mm with roll ring D220 |

| Hydraulic oil volume | 7 litres | 17 litres | 17 litres | 9 litres | 9 litres |

| Y-axis | |||||

| Shaft drive; individually driven! | Electric motors, clean and low noise | Electric motors, clean and low noise | Electric motors, clean and low noise | SERVO DRIVE - clean - low noise - 100% torque at any speed | SERVO DRIVE - clean - low noise - 100% torque at any speed |

| Dynamic speed control of the shafts | 1 – 30 rpm | 1 – 20 rpm | 1 – 22 rpm | 1 – 16 rpm | 1 – 8 rpm |

| Max. torque per shaft | 500 Nm | 800 Nm | 1600 Nm | 3000 Nm | 9000 Nm |

| Shaft height | 110 mm (optionally 220 mm) |

275 mm | 300 mm | 400 mm |

500 mm |

| Shaft diameter Ø | 40 mm | 40 mm 65 mm |

105 mm | 105 mm |

130 mm |

| Shaft supports | optional | series | series | series |

series |

| Front shaft distance | 256 (optional 80) – 518 mm | 110 - 800 mm | 200–1000 mm | 360-1120/1400 mm |

630–1330 mm |

| Z-axis | |||||

| Manual Z-axis (static) | series | series | series | - | - |

| Cranked Z-axis (dynamic) | optionally | optionally | optionally | optionally | - |

| CNC-controlled Z-axis (dynamic) | optionally 4 t | optionally 2 t | optionally 2 t or 4 t | optionally 4 t | series 4 t |

| Control / Software:: | |||||

| Machine control | Manual / Tablet Teach-In / TABLET350 / PC400 | PC400 | Manual / Tablet Teach-In / TABLET350 / PC400 | PC400 | PC400 |

| Operating system | Windows 10 | Windows 10 | Windows 10 | Windows 10 | Windows 10 |

| General technical data: | |||||

| Connection | 3 x 400 VAC, 16 A | 3 x 400 VAC, 20 A | 3 x 400 VAC, 32 A | 3 x 400 VAC, 32 A | 3 x 400 VAC, 62 A |

| KW | 2 kw | 4 kw | 7 kw | 15 kw | 34 kw |

| Length / width / height | 905 mm / 950 mm / 1125 mm | 1400 mm / 1450 mm / 1370 mm | 1680 mm / 1.250 mm / 1390 mm | 1970 mm / 1.860 mm / 1420 mm | 2520 mm / 2240 mm / 1760 mm |

| Weight | 540 kg | 1275 kg | 1150 kg | 2250 kg | 5500 kg |

| Transportability of the machine | Pallet truck | Pallet truck | Pallet truck / Drawbar | Crane | Crane |